SEMI-HERMETIC

Universal and environmentally friendly: ECOLINE reciprocating compressors offer high cooling capacity with minimal energy requirements and are optimised for HFC, HFO and low-GWP refrigerants.

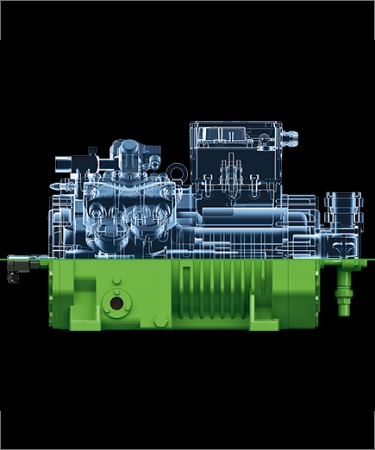

SEMI-HERMETIC 2-STAGE

The 2-stage reciprocating compressors are designed for an extensive application range and boast an optimised drive gear and efficient motor. The highly reliable semi-hermetic series is designed to be robust and suitable for a variety of refrigerants.

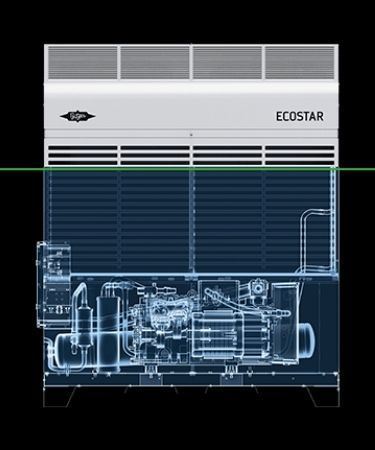

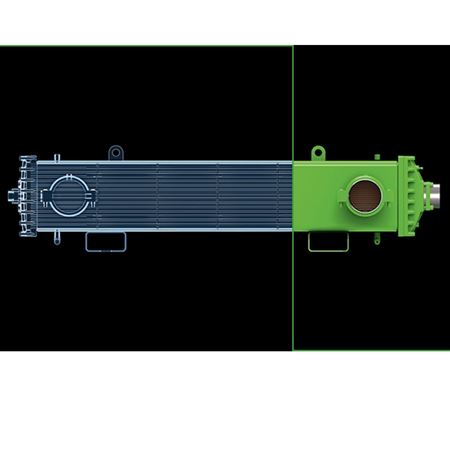

SCREW COMPRESSOR

Rotary Screw Air Compressor are a type of movement compressor that compresses air based on the activities of two opposite helical shaped screws. And thanks to their reliability, long lifetime and versatility, they are widely used in a lot of different industries. Compared to piston compressors, they are overall more efficient and flexible.

The functioning of the screw compressors varies depending on whether it is oil injected or oil free. For the oil injected system, one of the rotors (the male rotors) drive the female rotors.

The differentiate between the screw compressors and the piston compressor is the absence of valve and mechanical force in the former (which creates a lot of imbalance in the latter). As a result, screw compressors can work at a high flow rate and large speed. Therefore, they can produce high-pressure air in a taciturn manner.

For the oil-free system, the two opposite shafts/rotors (connected by time gears to match their speed) are rotated by the motor leading to the compression of incoming low-pressure air to result in high-pressure air.

Filter by:

Clear All